NSN 5325-00-263-2711

Part Details | RETAINING RING

5325-00-263-2711 A resilient metal item, circular or nearly circular, which is designed to be inserted into an internal or external groove and retained by its own spring action, or it may have external prongs or projections designed to be inserted into a hole and retained by spring action of the prongs which grip by imbedding into the material. For items having internal prongs which perform the same function, see PUSH ON NUT. It is used to keep and/or lock a part(s) in position, as a ball bearing on a shaft or in a housing. See also CLIP, RETAINING and PIN, LOCK. Excludes RING, CONNECTING, ROUND.

Alternate Parts: AA7C224, 864764, AA7C224, 153918, 571973, AA7C224, MS16631185, MS16631-185, N5002185, N5002-185, N5002185, N5002-185, 5325-00-263-2711, 00-263-2711, 5325002632711, 002632711

| Supply Group (FSG) | NSN Assigned | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 53 | JAN 01, 1963 | 00-263-2711 | 07623 ( RING, RETAINING ) |

REFERENCE DRAWINGS & PICTURES

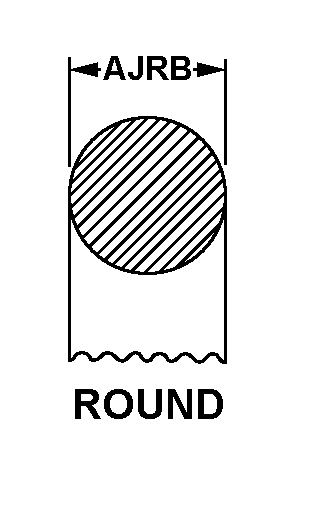

ROUND

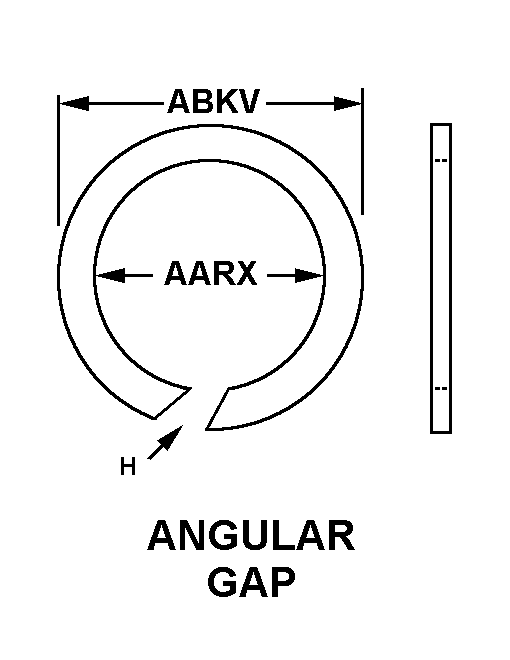

ANGULAR CAP

Cross Reference | NSN 5325-00-263-2711

| Part Number | Cage Code | Manufacturer |

|---|---|---|

| AA7C224 | 1H6M3 | AMERICAN TERRA VEHICLES INC |

| 864764 | 12603 | CLARK EQUIPMENT CO |

| AA7C224 | 50803 | DECO-GRAND INC SUB OF GRANDMACHINING CO |

| 153918 | 62983 | EATON AEROSPACE LLC |

| 571973 | 83299 | HYSTER-YALE GROUP, INC.DBA YALE MATERIALS HANDLING |

| AA7C224 | 02978 | L3 TECHNOLOGIES, INC.DBA COMBAT PROPULSION SYSTEMS |

| MS16631-185 | 96906 | MILITARY STANDARDSPROMULGATED BY MILITARY DEPARTMENTS |

| N5002-185 | 07382 | ROTOR CLIP COMPANY INC.DBA ROTOR CLAMP |

| N5002-185 | 79136 | TRUARC COMPANY LLCDBA WALDES TRUARC |

Technical Data | NSN 5325-00-263-2711

| Characteristic | Specifications |

|---|---|

| CASEHARDENING INDICATOR | NOT CASEHARDENED |

| RING STYLE | 7 ANGULAR CAP |

| CROSS-SECTIONAL SHAPE STYLE | 4 ROUND |

| USAGE DESIGN | INTERNAL |

| MATERIAL HARDNESS RATING | 47.0 ROCKWELL C MINIMUM AND 52.0 ROCKWELL C MAXIMUM |

| OUTSIDE DIAMETER | 1.985 INCHES MINIMUM AND 2.018 INCHES MAXIMUM |

| MINOR THICKNESS | 0.045 INCHES MINIMUM AND 0.047 INCHES MAXIMUM |

| MAJOR THICKNESS | 0.059 INCHES MINIMUM AND 0.065 INCHES MAXIMUM |